COMPOSTING OF BIOLOGICAL WASTE

ADDED VALUE FROM ORGANIC WASTE

The composting and anaerobic digestion of organic wastes and their return into the cycle of materials as high quality fertilizer and humus is well established worldwide.

As an integral part of the material cycle, our tunnel composting technology makes a valuable contribution to environmental protection and contributes significantly to reducing waste and conserving resources.

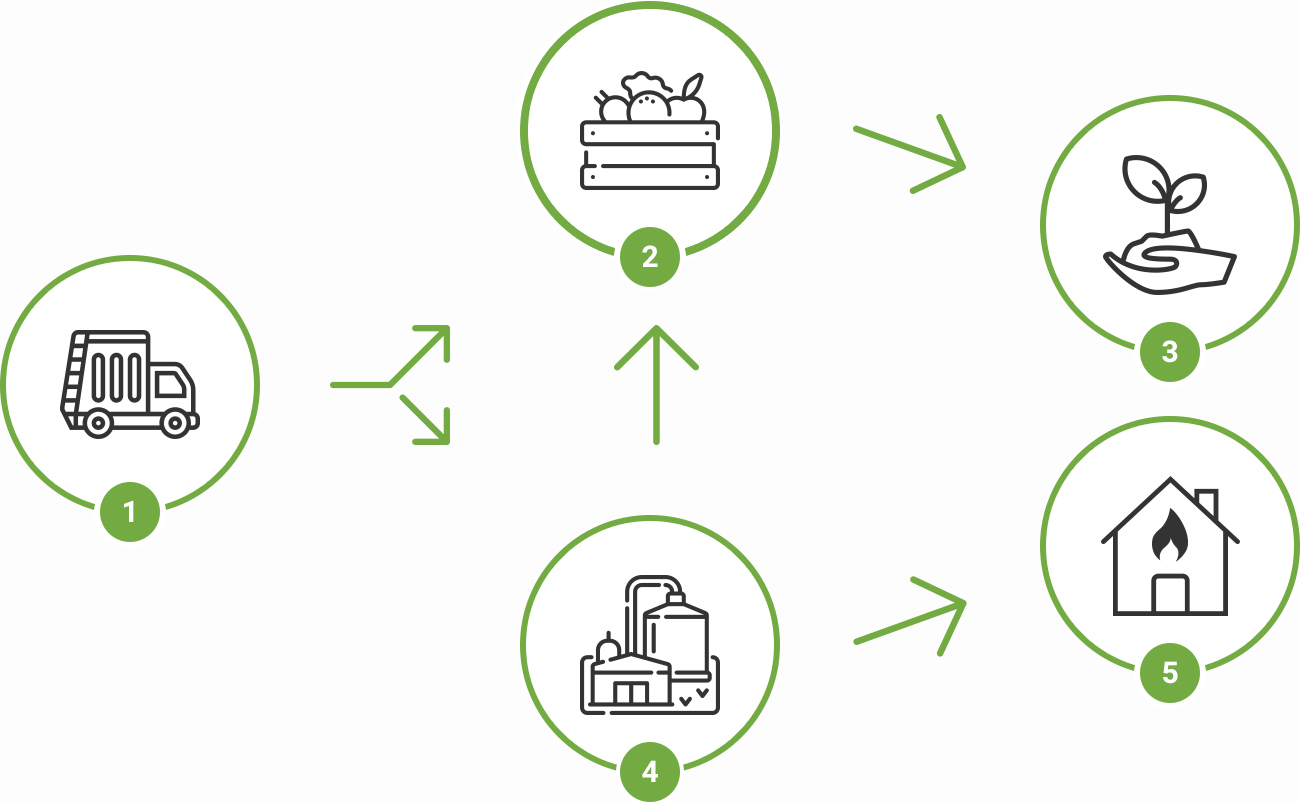

- Collection of organic waste

Organic waste is generated both in private households and in commercial enterprises. This waste is collected and can be supplied to Waste Tec composting plants. - Composting of organic waste and digestate as well as sewage sludge

In the Waste Tec tunnel composting system, organic wastes are efficiently composted and generally sanitized as well.

- Production of high quality compost

After composting in the Waste Tec tunnels, the compost is matured if required or directly conveyed to a mechanical treatment. - Fermentation of organic waste

In the absence of oxygen methan is produced in anaerobic digestion plants. - Production of biogas for the substitution of fossil fuels

The methane produced can be used as a substitute for fossil fuels.The digestate produced in the anaerobic digestion plant can be treated in an odourless way in the Waste Tec tunnel composting system.

Composting of untreated organics

In completely enclosed, process-controlled tunnels compost of the highest quality is produced from compostable organic material, like househould and garden waste, cuttings from trees and bushes, agricultural waste etc. In addition a reliable sanitation of waste is ensured. The closed design avoids the uncontrolled release of emissions and subsequently the exhaust air can be cleaned in accordance with the legal requirements.

To improve the composting process mechanical treatment steps (shredding, mixing etc.) can be used upstream.

A downstream separation of impurities guarantees the best possible compost quality.

Different types of waste require adapted pre-treatment steps to optimise the downstream composting process. For example, packaged waste delivered has to be unpacked and wood type waste needs to be shredded and defibrated. By mixing in structural material a best possible ventilation can be ensured.

Special mixing units or the mixture by front end loader are suitable for this purpose.

The composting tunnel equipped with aeration floor and process control allows a best possible composting of organic wastes and maximized throughput per unit area. In addition uncontrolled odour emissions are minimzed. On the basis of its boundary conditions, the client decides on the retention time of the waste in the tunnel and thus on the degree of rotting of the compost produced. Retention times of 7 days (fresh compost) to 28 days (mature compost) are common.

Depending on the legal requirements but also if an intensive rotting of 7 days is applied a windrow maturation outside, in a sheltered area or in a ventilated building is advisable.

In addition to the compost quality solely based on the degree of rotting, the degree of contamination by solid impurities (plastics, stones, glass, etc.) and the chemical burdens originating from the waste is also of a essential importance for the compost quality. The amount of solid impurities in the compost can be reduced by a mechanical treatment.

Screens, classifiers and optical sorters are suitable for this purpose.

Advantages of the WasteTec Tunnel Composting System:

- Fully enclosed intensive rotting with controlled exhaust air collection and exhaust air purification

- Quick achievement of the required degree of rotting (RG 2-5) by significantly reduced rotting times

- Assured sanitation of the compost produced

- Low space requirement

- Production of a high quality compost

Digestate and sewage sludge composting

Residues from the fermentation of organic wastes or digested (fermented) sewage sludge normally require a composting before utilisation. The composting transfers the anaerobic digestate into an aerobic environment and in addition (if required) the organic material is sanitised and odour is significantly reduced.

For this composting process the completely enclosed, process-controlled Waste Tec tunnel composting system is perfectly suited. Together with an appropriate mechanical pre- and post treatment a compost free of impurities is produced.

Different fermentation residues require adapted pre-treatment steps to optimize the subsequent composting process.

For the production of a ventilatable substrate the mixture with shredded / defibrated wood type materials is required in particular. This can be produced by using special mixing units or front end loaders.

The composting tunnel equipped with the aeration floor allows a controlled and process monitored composting of digestate respectively sewage sludge and thus maximizing of throughput per unit area. In addition uncontrolled odour emissions are minimzed.

To produce a high quality compost generally a retention time of 7 days is sufficient. An additional sanitazion would extend the process time.

In addition to the compost quality solely based on the degree of rotting, the degree of contamination by solid impurities (plastics, stones, glass, etc.) and the chemical burdens originating from the waste is also of a essential importance for the compost quality. The amount of solid impurities in the compost can be reduced by a mechanical treatment.

Screens, classifiers and optical sorters are suitable for this purpose.

Advantages of the WasteTec digestate and sewage sludge tunnel composting system:

- Fully enclosed intensive rotting with controlled exhaust air collection and exhaust air purification

- Assured sanitation of the compost produced (in case of mesophilic fermentation), if required

- Low space requirement

- Production of a high quality digestate respectively sewage sludge compost